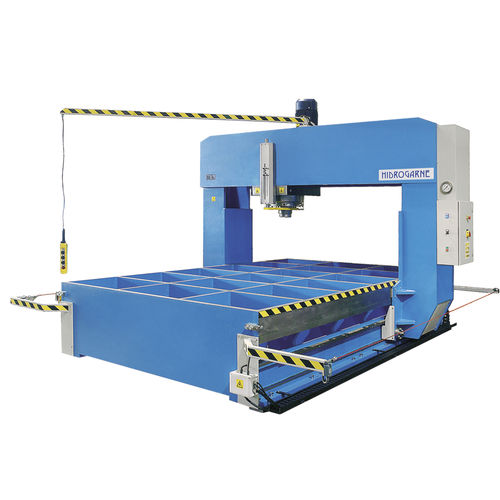

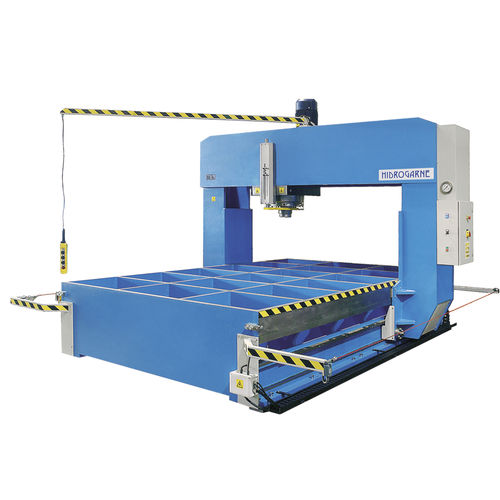

Straightening and Bending Presses T Series

Product Description

Straightening and Bending Presses T Series;

Specifically designed for straightening electro-welded structures and flame cut sheets. Their design makes it easy to load and unload large-volume parts. Thanks to the lateral displacement of the roller and the longitudinal displacement of the bridge, different clamping points are achieved without the need to move the part. It consists of an electro-welded structure made only of S355JR steel. At the end of the structural welding process is stabilized and processed. The longitudinal displacement of the bridge is motorized, controlled by a frequency inverter and driven by a toothed belt. The lateral displacement of the head is motorized and is controlled by a frequency inverter on models 220 and 300 Tn. The cylinder is double-acting with a chrome plunger and maintenance-free anti-wear guides, equipped with a replaceable press plate to prevent piston breakdown and ultimately adapt to the tools. The fact that the cylinder does not rotate with a square front and stroke end is standard, allowing us to easily regulate the cylinder stroke. The motorized 2-speed hydraulic unit has automatic quick-release. Includes a cylinder decompression valve. A pressure regulator comes as standard. Pressure is less than 320 bar. Glycerin measures tone with reading. The control panel includes a switch that allows the user to select the desired operating type in manual or semi-automatic position. Operation is performed with a low voltage pendant control station. Includes emergency stop and maneuver confirmation button.

Trade Areas

Phone:

E-Mail:

Support

Copyright Netetrade 2025. Developed by Yartu Labs