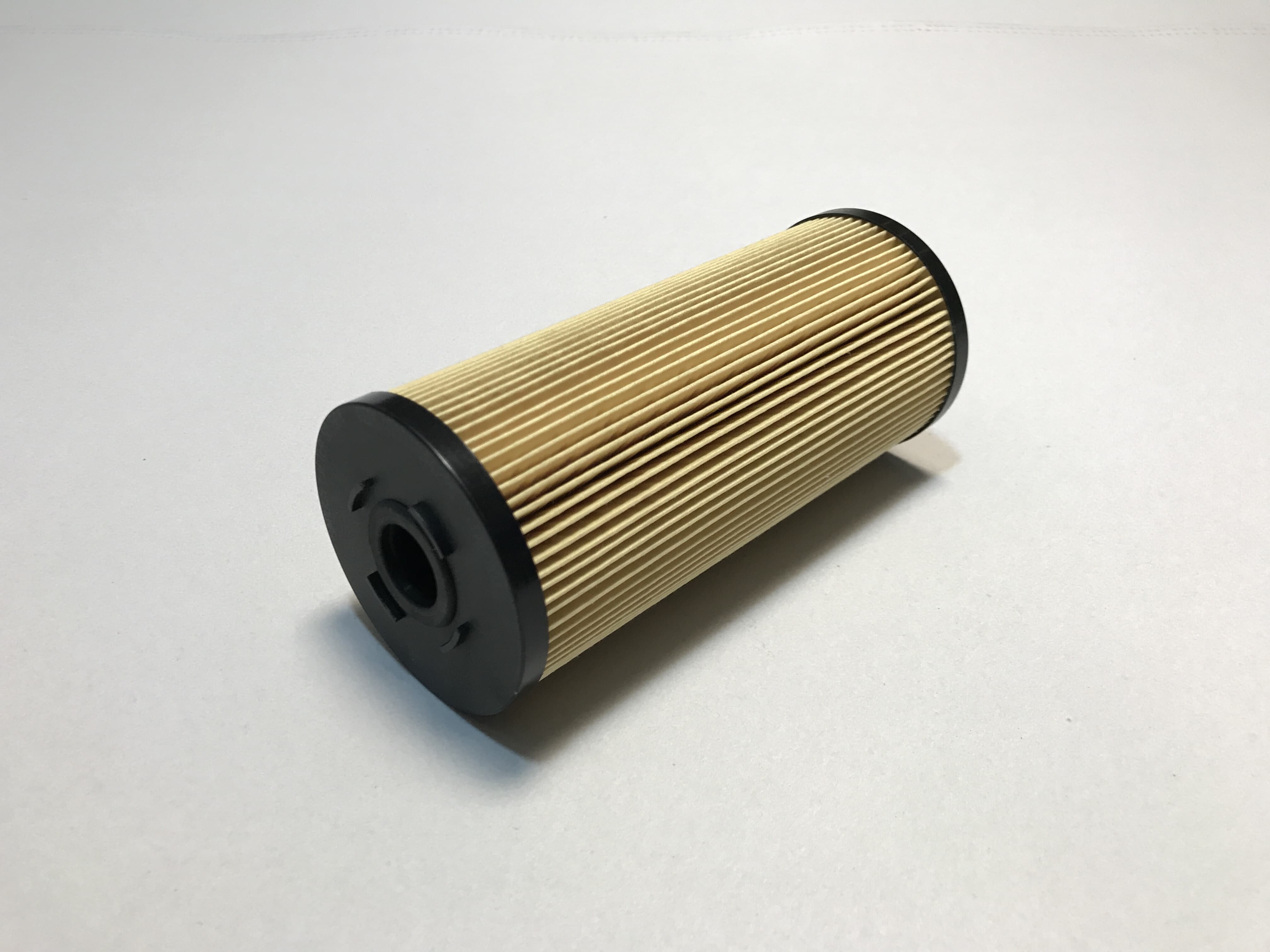

stone grinding diamonds

Product Description

stone grinding diamonds;

Cladding and straightening of abrasive grinding disc surfaces is one of the most important elements of achieving high levels of precision and excellence in grinding operations. Numerous grinding operations make grinding wheels lose their cutting edges and become polished and dull. By dressing the abrasive grinding surface (after straightening), optimum cutting ability can be recovered. The dressing prevents the accumulation of waste deposits from the rim surface, such as steel residues and hard dust particles. The dressing also cleans a small amount of adhesion from the wheel surface, effectively releases abrasives and improves cutting performance. Truing is the process by which unwanted wear is removed from the wheel surface after the wheel is installed. The treatment must first be carried out by wetting the surface of the wheel. Effective dressing can be achieved by means of diamond threaders, single point diamond threaders, impregnated diamond threaders and multi-point diamond threaders that form four different dressing tools.

Trade Areas

Phone:

E-Mail:

Support

Copyright Netetrade 2025. Developed by Yartu Labs